[15:53 Thu,24.September 2020 by Thomas Richter] |

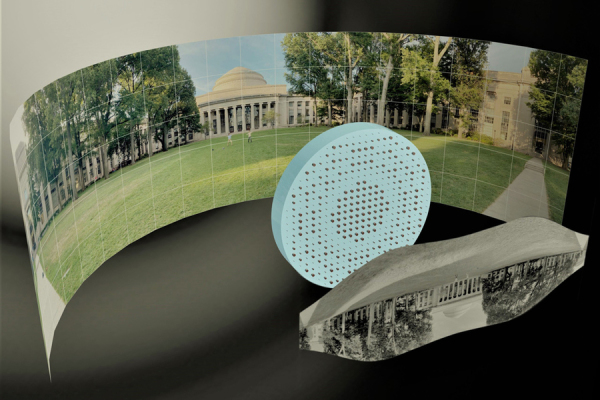

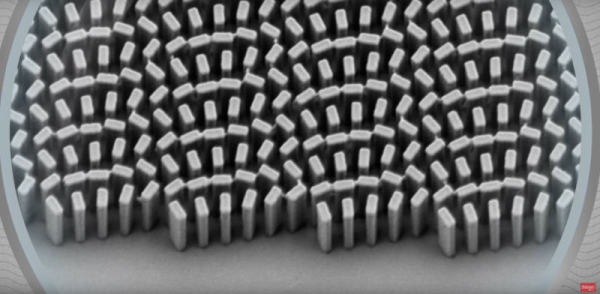

Researchers at MIT have turned a single 1mm flat glass plate into a 180° fisheye lens. They have used the new metal lens technology, which has the potential to lead to great advances in optical technology. In contrast to traditional methods where lenses are assembled from lenses of different thickness and curvature, metal lenses get their special optical properties by exact microscopic changes of the surface of a single thin glass pane. The glass pane of the new 180° fisheye lens is made of calcium fluoride and has a thin coating of lead telluride on one side, into which a pattern of tiny optical structures has been scratched using high-resolution lithographic processes. Each of these "meta-atom" structures consists of a specific shape that reflects light in a certain way. Classical lens technology changes the travel time of light using lenses of varying thickness and curvature - metal lenses achieve the same effect using microstructures that scatter the light or direct it from one structure to another, thus also changing its travel time.  Fisheye Metal Lens With conventional fisheye lenses, the curvature of the glass naturally creates a distribution of phase delays, which ultimately results in a panoramic image. The MIT research team calculated a corresponding meta-atomic pattern with a similar effect and carved this pattern into the back of the fisheye glass. The metal lens fisheye thus provides an almost perfect quality throughout the entire 180° field of view of the image without distortion.  Metal lens surface structure For the time being, the new fisheye works only in the infrared range of light - but the researchers are confident that they will soon be able to modify it so that it also works in the visible range. When will the metal lens revolution come? Metal lenses could trigger a revolution in the production of lenses, as they are significantly flatter than conventional lenses, thus enabling systems that are unmatched in terms of lightness, compactness and cost effectiveness. In metal lenses, the microstructures are designed and distributed in such a way that the light behind them converges at a focal point, just like in a conventional lens. Meta-surfaces can also be designed to mimic the functionalities of other optical components, such as beam splitters, polarizers or diffraction gratings. Even functions such as image stabilization or zoom could be realized by changing the microstructures via electrical fields. Moreover, metal lenses are achromatic by nature. In research projects, metal lenses are still produced in a complex process using electron beam lithography and are therefore still very small with a size in the micrometer range. In the future, however, metal lenses could be produced at a fraction of the cost of conventional lenses but with the proven photolithographic processes of chip manufacture with larger diameters in the millimeter range and in masses, for example for applications where particularly flat and compact optics are required, such as for cameras in smartphones, tablets or very small drones. Anyone interested in the technology behind metal lenses can find out more at deutsche Version dieser Seite: Metalinse macht aus flachem Glas perfektes 180°-Fisheye |